Hi, new to forum, access n00b.

Maybe in the wrong place, this may be achievable in excel.

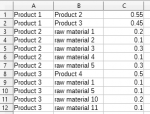

I have raw data that is exported from a program in this format.

product raw material amount

Product 1 raw material 1 54

Product 1 raw material 2 41

Product 1 raw material 3 1

Product 1 raw material 4 45

Product 1 raw material 5 45

Product 2 raw material 2 45

Product 2 raw material 4 4

Product 2 raw material 7 53

Product 2 raw material 1 54

Product 2 raw material 3 5

Product 3 Product 1 5

Product 3 Product 2 57

it is recipes / formulations for products. as you can see each product is repeated for each raw material it contains.

I want to be able to search the data for products that contain particular raw materials, ie. which products contain raw material 1 and raw material 2 for example.

would i need to normalise the data?

also potentially i want to create a system whereby documents could be generated for a product describing its properties based on its recipe. so for example if it contained raw material 1 it would be described as flammable. if it contained raw material 2 it might be described as solid.

preferably these two systems would have some form to be completed that a non tech savvy person could use.

Please could you help guide me in the right direction?

Maybe in the wrong place, this may be achievable in excel.

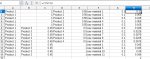

I have raw data that is exported from a program in this format.

product raw material amount

Product 1 raw material 1 54

Product 1 raw material 2 41

Product 1 raw material 3 1

Product 1 raw material 4 45

Product 1 raw material 5 45

Product 2 raw material 2 45

Product 2 raw material 4 4

Product 2 raw material 7 53

Product 2 raw material 1 54

Product 2 raw material 3 5

Product 3 Product 1 5

Product 3 Product 2 57

it is recipes / formulations for products. as you can see each product is repeated for each raw material it contains.

I want to be able to search the data for products that contain particular raw materials, ie. which products contain raw material 1 and raw material 2 for example.

would i need to normalise the data?

also potentially i want to create a system whereby documents could be generated for a product describing its properties based on its recipe. so for example if it contained raw material 1 it would be described as flammable. if it contained raw material 2 it might be described as solid.

preferably these two systems would have some form to be completed that a non tech savvy person could use.

Please could you help guide me in the right direction?