Hi,

I have just recently joined a new company, and one of my tasks is to see if it is possible to convert 5-6 separate excel inventory files into one access database.

I have little prior experience with database design, and have started by googling, trying to find examples I can adopt.

We currently have one 'master parts' excel file, listing all inventory items. Parts used in production plus all other items in the company, like furniture, coffee machines, PC's, switches, spare parts etc. The 'master parts' excel file currently have 5000+ rows, and keeps growing as we identify and register new items into that file.

We use a barcode scanner to manage inventory in the 'master parts' excel sheet (parts in/out, parts counting etc.) These tasks is performed by several excel VBA macros, triggered by the barcode scanner. All VBA scripts is stored in a macro enabled excel sheet, triggered to run by the barcode scanner.

Currently, each part type have their own excel inventory file, with their own part naming convention. For example, the 'Equipment' excel file have a list of all equipments, with unique names like 'EQU.XXXX' where XXXX is incremented by one for every new equipment registered. Then the same for instruments (INST.XXXX), lifting equipment (LFT.XXXX) etc.

At the moment, we have about 6 or 7 of these individual inventory excel files.

As for the 'Master Parts' excel file, we have ordinary parts used in the workshop and production together with MRO products (Maintenance, Repair and Office supplies). For the 'ordinary' parts, we use the supplier's partnumber, if possible.

Then we manually add all the parts from the individual inventory excel files into that same master parts file, so that we can easily use the barcode scanner to scan parts in/out.

Parts scanned in/out is added to two or more 'parts used by project' excel files (performed by the excel VBA script mentioned earlier), and that 'parts used by project' is manually copied or in some cases moved into other excel files used by accounting for invoicing etc.

Some of the inventory excel files have lots of columns for special information required by each part type, and the master parts excel file currently have some 90+ columns.....making it really easy to get lost and make mistakes.

Currently, adding new parts to the individual inventory excel files and then into the master parts file is done manually.

I have started to create an access database to eventually replace all these individual excel sheets, but are currently stuck on how to add parts into the master database from the individual inventory excel files. How do I create a form where users can just click the 'add new part' button, select 'part type' (equipment, instrument etc), and then be guided through entering correct information. On that same topic, how do I structure the tables in such a way that they get their own unique naming convention, and at the same time, is added to that master table?

And how do I assign a scannable unique identifier into the master database? We want to be able to identify part types by the label we create and stick to each item. Label include barcode (QR code, to be precise, for example EQU.1013, INST.1014 etc), text representation of the barcode, and name+description of item. Where suppliers partnumber is used, that will be the QR code to use.

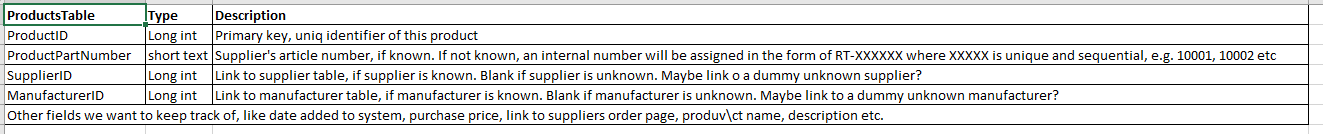

In the process we will also create new tables for transactions, suppliers, manufacturers, alternative suppliers, products etc.

As for products table, we want each unique product in a table, and then assign either an internal ID, a EQU, INST etc ID, and then the master parts table and individual inventory tables links to the products table for individual product details.

Could anyone give some pointers where to look for how to solve the issue with all the individual inventory excel files (or tables)?

Any hint, suggestion or pointer would be appreciated.

I have just recently joined a new company, and one of my tasks is to see if it is possible to convert 5-6 separate excel inventory files into one access database.

I have little prior experience with database design, and have started by googling, trying to find examples I can adopt.

We currently have one 'master parts' excel file, listing all inventory items. Parts used in production plus all other items in the company, like furniture, coffee machines, PC's, switches, spare parts etc. The 'master parts' excel file currently have 5000+ rows, and keeps growing as we identify and register new items into that file.

We use a barcode scanner to manage inventory in the 'master parts' excel sheet (parts in/out, parts counting etc.) These tasks is performed by several excel VBA macros, triggered by the barcode scanner. All VBA scripts is stored in a macro enabled excel sheet, triggered to run by the barcode scanner.

Currently, each part type have their own excel inventory file, with their own part naming convention. For example, the 'Equipment' excel file have a list of all equipments, with unique names like 'EQU.XXXX' where XXXX is incremented by one for every new equipment registered. Then the same for instruments (INST.XXXX), lifting equipment (LFT.XXXX) etc.

At the moment, we have about 6 or 7 of these individual inventory excel files.

As for the 'Master Parts' excel file, we have ordinary parts used in the workshop and production together with MRO products (Maintenance, Repair and Office supplies). For the 'ordinary' parts, we use the supplier's partnumber, if possible.

Then we manually add all the parts from the individual inventory excel files into that same master parts file, so that we can easily use the barcode scanner to scan parts in/out.

Parts scanned in/out is added to two or more 'parts used by project' excel files (performed by the excel VBA script mentioned earlier), and that 'parts used by project' is manually copied or in some cases moved into other excel files used by accounting for invoicing etc.

Some of the inventory excel files have lots of columns for special information required by each part type, and the master parts excel file currently have some 90+ columns.....making it really easy to get lost and make mistakes.

Currently, adding new parts to the individual inventory excel files and then into the master parts file is done manually.

I have started to create an access database to eventually replace all these individual excel sheets, but are currently stuck on how to add parts into the master database from the individual inventory excel files. How do I create a form where users can just click the 'add new part' button, select 'part type' (equipment, instrument etc), and then be guided through entering correct information. On that same topic, how do I structure the tables in such a way that they get their own unique naming convention, and at the same time, is added to that master table?

And how do I assign a scannable unique identifier into the master database? We want to be able to identify part types by the label we create and stick to each item. Label include barcode (QR code, to be precise, for example EQU.1013, INST.1014 etc), text representation of the barcode, and name+description of item. Where suppliers partnumber is used, that will be the QR code to use.

In the process we will also create new tables for transactions, suppliers, manufacturers, alternative suppliers, products etc.

As for products table, we want each unique product in a table, and then assign either an internal ID, a EQU, INST etc ID, and then the master parts table and individual inventory tables links to the products table for individual product details.

Could anyone give some pointers where to look for how to solve the issue with all the individual inventory excel files (or tables)?

Any hint, suggestion or pointer would be appreciated.