I'm trying to understand how FIFO is handled in an Access database.

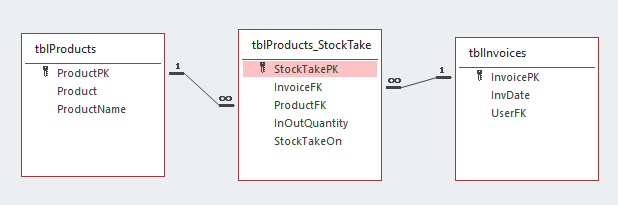

To learn about FIFO, I've started with a simple structure like this.

Well, I don't know what would the next step be. Do I need another field for controlling FIFO or do I need another table. I've tried to find a sample database but failed to find any.

Edit (based on the feed back I received bellow):

In this case, FIFO is going to control a production line of plastic injection machines. We don't want to keep old ABS material in inventory. The price is not of a concern in this particular case. We need to manage what is brought in first, being sent out of the inventory first. That's all.

If it makes sense. Simple as that. First In, First out. Without price.

Any kind of advice on this is appreciated.

To learn about FIFO, I've started with a simple structure like this.

Well, I don't know what would the next step be. Do I need another field for controlling FIFO or do I need another table. I've tried to find a sample database but failed to find any.

Edit (based on the feed back I received bellow):

In this case, FIFO is going to control a production line of plastic injection machines. We don't want to keep old ABS material in inventory. The price is not of a concern in this particular case. We need to manage what is brought in first, being sent out of the inventory first. That's all.

If it makes sense. Simple as that. First In, First out. Without price.

Any kind of advice on this is appreciated.

Last edited: