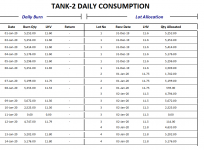

I need help designing FIFO Based Stock for Diesel Tanks, There are 2 Diesel Tanks. Fuel is received via Tankers. Each tanker has a different Price and Chemical Properties.

Normally 1 tank will be on Filling and the other will be In-Service. I have a Calculator to correct the received Tanker Volume with Temperature and the Corrected Volume will be considered received fuel. The consumption form will be updated on daily basis.

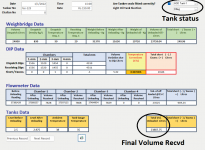

I have attached the Tanker Received Form in which the circled value is to be considered as Received Volume. Now the issue is how can I check the Stock Flow as per FIFO Method.

Normally 1 tank will be on Filling and the other will be In-Service. I have a Calculator to correct the received Tanker Volume with Temperature and the Corrected Volume will be considered received fuel. The consumption form will be updated on daily basis.

I have attached the Tanker Received Form in which the circled value is to be considered as Received Volume. Now the issue is how can I check the Stock Flow as per FIFO Method.