Hi,

I'm currently working on building out an access database to help my company with basically Inventory tracking. I have taken classes in the past with access so I'm not completely new, but haven't touched it in years so I'm running into some basic issues. Just want to get your opinions on if I'm getting onto the right track and any advise is appreciated. The basic connections I can get to work, It's now getting into the complex and basically a BOM situation.

My company has a Raw Material that is ran off of a tool. This tool can either be 1 part number or a left and a right part (2 part numbers). So, basically 1 sheet can either give you 1 part, or 2 parts depending on the tool.

1 Material = 1 part OR 2 individual parts dependent on the part number.

The Idea is I'll create a unique AlternateID for these combo parts, using PID1 and PID2 (two different part numbers). That Alternate ID will pull from the Raw Sheet (Material ID) which will subtract 1 total sheet, and add to two different part numbers in Inventory.

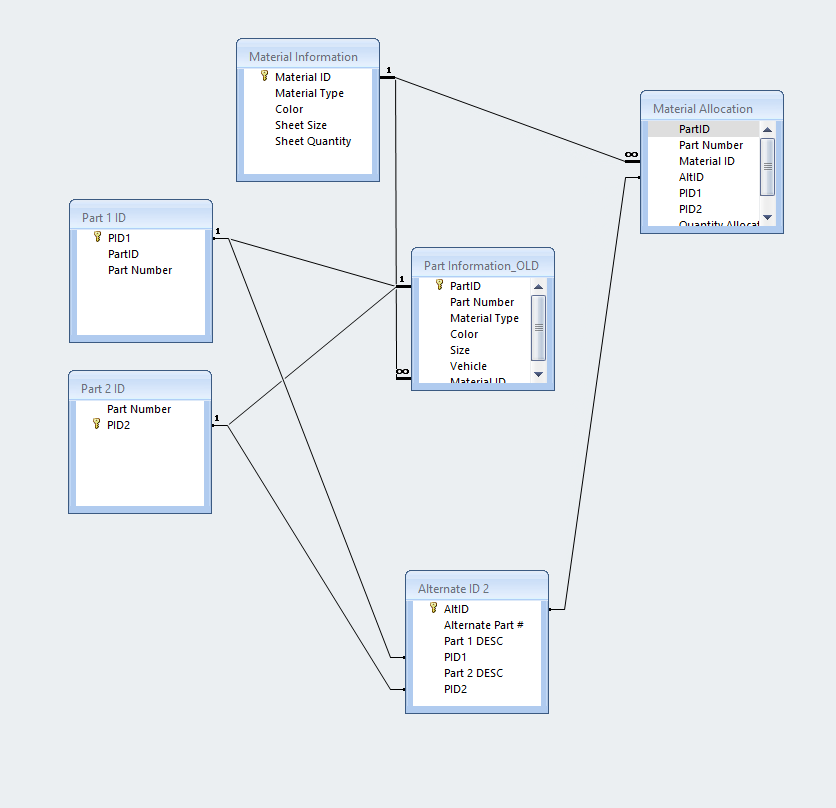

Here is the screenshot of my current set up. This is my test database so it's bare bones right now.

I believe my connection for Part Information to Material Information is great, but I think there may be an easier or simpler way to do the Alternate ID table. Referential Integrity does not work even though its Number to Number formats. Also, down the road I'm not sure if this set up will also calculate the single part numbers (1 sheet = 1 part) as it is not referenced in the Alt ID table.

Any suggestions?

Thanks,

J

I'm currently working on building out an access database to help my company with basically Inventory tracking. I have taken classes in the past with access so I'm not completely new, but haven't touched it in years so I'm running into some basic issues. Just want to get your opinions on if I'm getting onto the right track and any advise is appreciated. The basic connections I can get to work, It's now getting into the complex and basically a BOM situation.

My company has a Raw Material that is ran off of a tool. This tool can either be 1 part number or a left and a right part (2 part numbers). So, basically 1 sheet can either give you 1 part, or 2 parts depending on the tool.

1 Material = 1 part OR 2 individual parts dependent on the part number.

The Idea is I'll create a unique AlternateID for these combo parts, using PID1 and PID2 (two different part numbers). That Alternate ID will pull from the Raw Sheet (Material ID) which will subtract 1 total sheet, and add to two different part numbers in Inventory.

Here is the screenshot of my current set up. This is my test database so it's bare bones right now.

I believe my connection for Part Information to Material Information is great, but I think there may be an easier or simpler way to do the Alternate ID table. Referential Integrity does not work even though its Number to Number formats. Also, down the road I'm not sure if this set up will also calculate the single part numbers (1 sheet = 1 part) as it is not referenced in the Alt ID table.

Any suggestions?

Thanks,

J