Good morning, new member here.

I was hoping someone could help me with an example or terminology for a database that keeps records of the serial numbers that have gone into the equipment that we assemble.

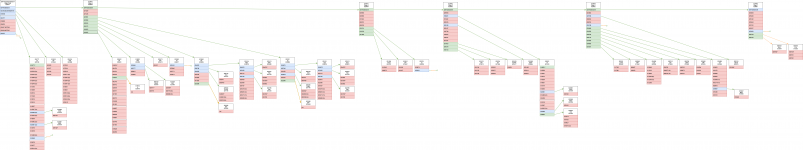

Since the equipment has several sub assemblies; graphically this would look like a tree diagram with a root, branches (up to 6 deep), and ~300 nodes.

We currently store this data in a flat file (excel) but this has the major drawback that it is not easy to swap or replace nodes should service occur on the equipment.

Please let me what other additional information would be helpful. I can not post the flat file for privacy reasons.

Thanks,

Joe

I was hoping someone could help me with an example or terminology for a database that keeps records of the serial numbers that have gone into the equipment that we assemble.

Since the equipment has several sub assemblies; graphically this would look like a tree diagram with a root, branches (up to 6 deep), and ~300 nodes.

We currently store this data in a flat file (excel) but this has the major drawback that it is not easy to swap or replace nodes should service occur on the equipment.

Please let me what other additional information would be helpful. I can not post the flat file for privacy reasons.

Thanks,

Joe