hullstorage

Registered User.

- Local time

- Today, 23:51

- Joined

- Jul 18, 2007

- Messages

- 213

Hi all,

I will keep this as simple as i can so not to confuse anyone i hope lol

I am trying to create a database to log all stock items coming in and going out to and from carriers or couriers as currently this is all done manually.

When goods come in this can be 1 item or 20 items and they will have 1 unique order number and 1 unique waybill, this also applies for goods going out ?

(Goods In)

All goods that come in will have an Order number and waybill that must be logged against every item(s)

(Goods Out)

All goods that go out will have a Shipment Number and Waybill also that must be logged (these will be from above goods in that have previously been booked in)

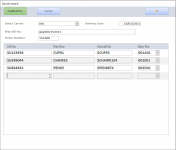

I want to say enter order number, waybill then have a subform to scan in the part details and dont want to keep having to scan in order number and waybill numbers for every part if there are multiple items (please see attached pic to give some idea)

I also cant figure out what is best for goods out, do i simply duplicate goods in and rename a few fields ? or do i need relationships

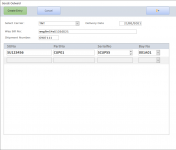

Ideally i would like to enter the shipment number, waybill number then when i scan the su number in the subform this will pull data from goods in table like part number, serial number etc ?

Any advice will be much appreciated.

I will keep this as simple as i can so not to confuse anyone i hope lol

I am trying to create a database to log all stock items coming in and going out to and from carriers or couriers as currently this is all done manually.

When goods come in this can be 1 item or 20 items and they will have 1 unique order number and 1 unique waybill, this also applies for goods going out ?

(Goods In)

All goods that come in will have an Order number and waybill that must be logged against every item(s)

(Goods Out)

All goods that go out will have a Shipment Number and Waybill also that must be logged (these will be from above goods in that have previously been booked in)

I want to say enter order number, waybill then have a subform to scan in the part details and dont want to keep having to scan in order number and waybill numbers for every part if there are multiple items (please see attached pic to give some idea)

I also cant figure out what is best for goods out, do i simply duplicate goods in and rename a few fields ? or do i need relationships

Ideally i would like to enter the shipment number, waybill number then when i scan the su number in the subform this will pull data from goods in table like part number, serial number etc ?

Any advice will be much appreciated.