I am after some code/advice for Access.

I have a list of Order Numbers(Unique) and what cubic metres that each are, I also have a cost benefit per Order.

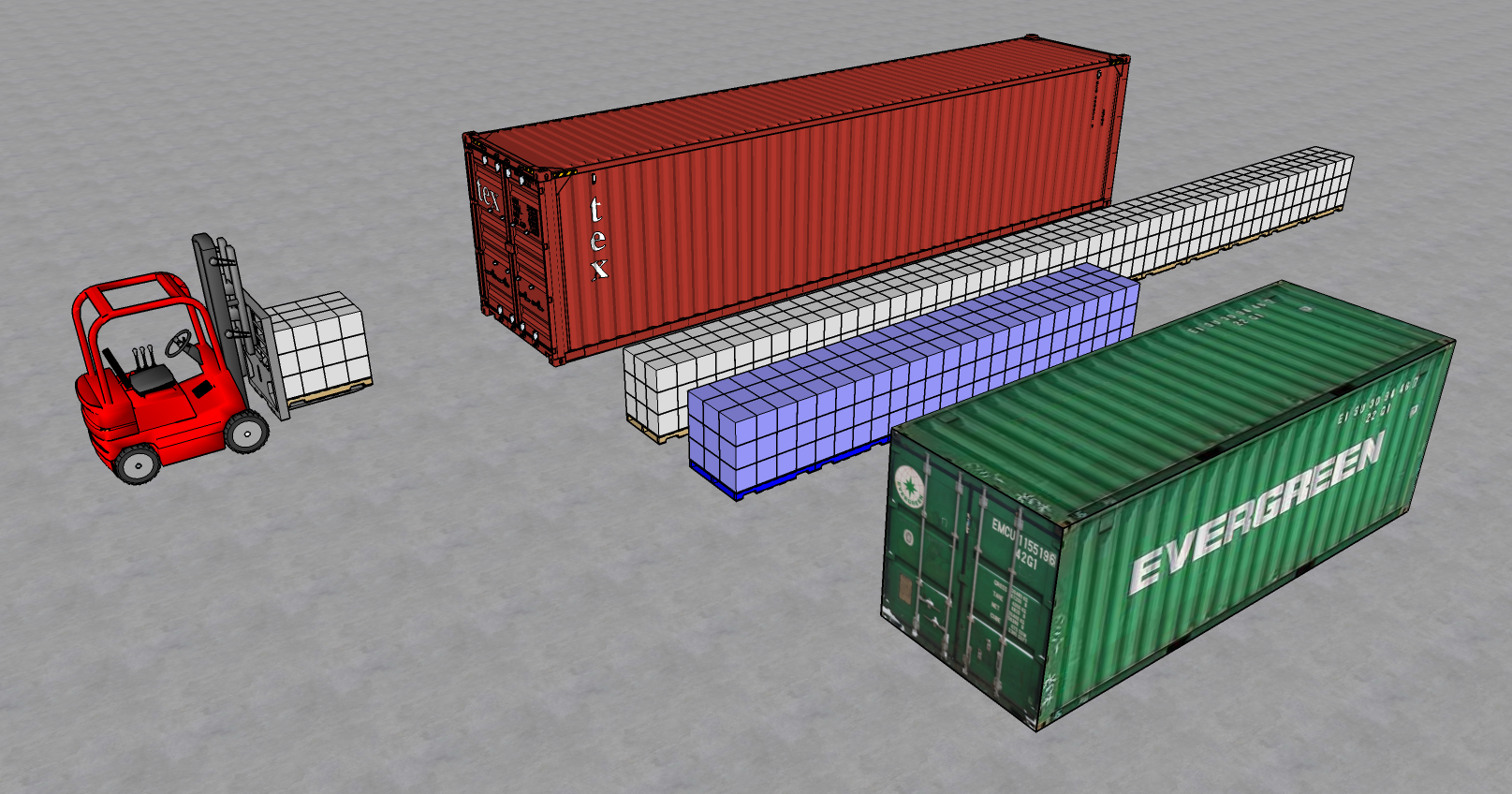

I would like to run some code to be able to find every combination of Orders but within a given constraint of Cubic size (65Cube) to find the most cost effect mix of Orders in the minimum amount of results (Lowest Container Loads)

So if I had for instance 9x PO's below, in this case due to them all being 20Cube, the minimum you could build would be 3 containers, but which combo would (not duplicating) output the highest cost benefit.

11111 20Cu £600

22222 20Cu £2,500

33333 20Cu £30,000

44444 20Cu £10,000

55555 20Cu £300

66666 20Cu £23,000

77777 20Cu £50,000

88888 20Cu £100

99999 20Cu £1,000

There are 84x Combinations in this case and top three would be:

333333 666666 777777

222222 444444 999999

111111 555555 888888

In the real case, there shall be 1800+ PO's and all of different cube.

I have a list of Order Numbers(Unique) and what cubic metres that each are, I also have a cost benefit per Order.

I would like to run some code to be able to find every combination of Orders but within a given constraint of Cubic size (65Cube) to find the most cost effect mix of Orders in the minimum amount of results (Lowest Container Loads)

So if I had for instance 9x PO's below, in this case due to them all being 20Cube, the minimum you could build would be 3 containers, but which combo would (not duplicating) output the highest cost benefit.

11111 20Cu £600

22222 20Cu £2,500

33333 20Cu £30,000

44444 20Cu £10,000

55555 20Cu £300

66666 20Cu £23,000

77777 20Cu £50,000

88888 20Cu £100

99999 20Cu £1,000

There are 84x Combinations in this case and top three would be:

333333 666666 777777

222222 444444 999999

111111 555555 888888

In the real case, there shall be 1800+ PO's and all of different cube.