CuriousGeo

Registered User.

- Local time

- Yesterday, 19:31

- Joined

- Oct 15, 2012

- Messages

- 59

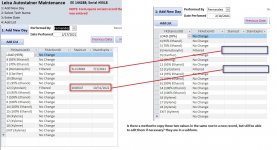

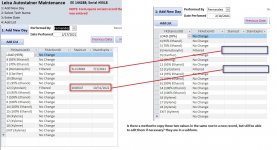

Hello, I have a maintenance database for an instrument that stains biological samples on glass slides. There are a series of containers with different chemicals in them. Of these, a few have Lot numbers and Expiration dates that are necessary to keep track of. The reason for copying them from day to day is because the lots last several months at a time.

The items in the subform are added by using the "Add List" button, which adds the items by insert:

' see if BOTH Name and Date Field are entered

If Len(TechName) > 0 And Len(fldDatePerformed) > 0 Then

DoCmd.SetWarnings False

DoCmd.RunSQL ("Insert INTO tblStainData (FKMasterID, FKStainListID) SELECT " & Me.masterID & ", tblStainList.listID FROM tblStainList WHERE (((tblStainList.Default)=Yes))")

DoCmd.SetWarnings True

End If

Me.Refresh

End Sub

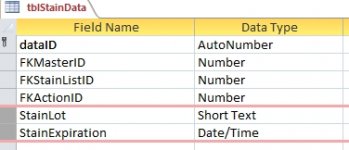

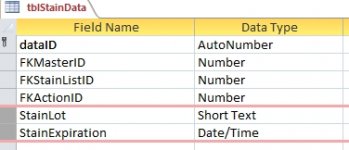

The items all come from the same table.

That table is below:

Two questions:

1. Am I doing this set-up correctly, or should the StainLot and Expiration be in a separate table?

2. Is there a way to copy those two values from those fields into subsequent (new) records, until the lot is used up and we change it?

The items in the subform are added by using the "Add List" button, which adds the items by insert:

' see if BOTH Name and Date Field are entered

If Len(TechName) > 0 And Len(fldDatePerformed) > 0 Then

DoCmd.SetWarnings False

DoCmd.RunSQL ("Insert INTO tblStainData (FKMasterID, FKStainListID) SELECT " & Me.masterID & ", tblStainList.listID FROM tblStainList WHERE (((tblStainList.Default)=Yes))")

DoCmd.SetWarnings True

End If

Me.Refresh

End Sub

The items all come from the same table.

That table is below:

Two questions:

1. Am I doing this set-up correctly, or should the StainLot and Expiration be in a separate table?

2. Is there a way to copy those two values from those fields into subsequent (new) records, until the lot is used up and we change it?

Last edited: