and I was surprised that it didn't already manage inventory in order to inform the traceability.

@gemma-the-husky

As I explained in PM, that was for line 2 & 3 (machining) and the system you're talking about is under the last stage of testing. It will be on-line from 2023/01/01

This question was for Line 4 (Sheetmetal). And as I explained at present this production line doesn't need an inventory.

I'm confused about why you would be breaking down the assemblies in an order entry system.

@Pat Hartman I'm sure how many times I try to explain, it would be hard to understand it. let me give you an example.

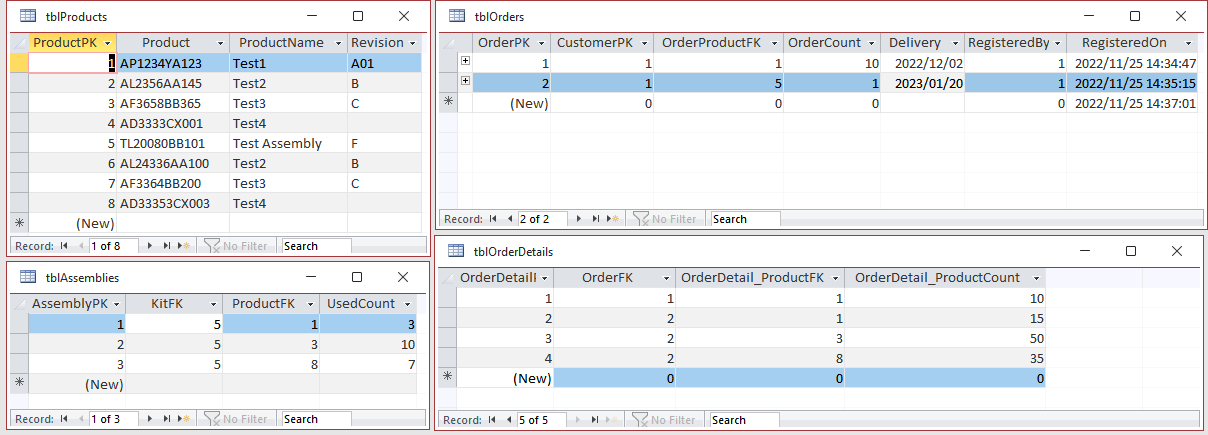

An average assembly has 50 to 400 components. I take the following assembly as an example. It has 352 parts. Get ride of the ready made components (screws, hinge, etc). 311 components are left. All of these 311 components are our products.

We have received an order for this assembly. (3200 Pcs)

From the point of ordering, it's only one order with the quantity of 3200. I understand it. And as you expect there should be only one record for this order in order table. You are correct up to this point.

But from the point of production, we have to manufacture 312 component. For us, it's not one order. We have to manufacture 312 products. And We need to be able to trace the production processes, who has done what, which machine and operator? is it finished? if not at what stage of production it is? when will it available for being assembled? etc.

Sometimes the customer calls us and asks if it is possible to do some changes to one of those 312 components. We can not leave our desks and spread in the whole company to find out the progress of that specific component. OR where it is? who is in charge of its production? etc. Every piece of data about that assembly and it's components should be available for us at any moment.

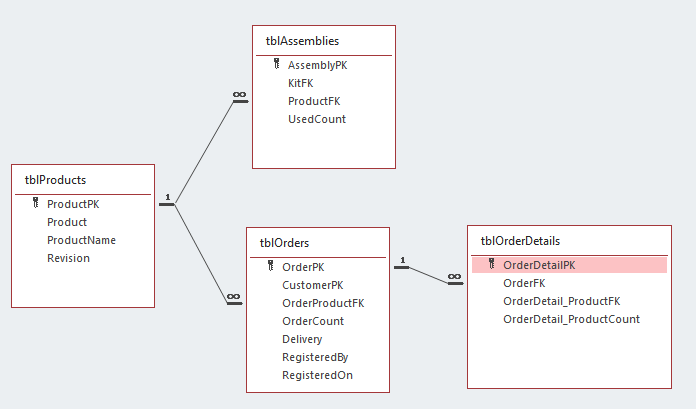

To be able to have this information, we have an Order table and a DetailedOder table. Even if it's one order, we save all the components in the detailed table. Then there's a processes table that has a FK to to detail table's PK. (one to many relation). The processes of each those 312 components are saved in the process table.

This is the search result of one of those component.

This is the situation of one of those 312 components.

The left side is the single form of tblOrdersDetail. The right side is a continuous sub form linked to process table.

The blue rectangle is the assembly we have to produce. (It's shown here only with dLookup from tblOrders).

At the left side, you can see the process and who and when it's been done. The empty textboxes shows that process has not been processed yet.

the filled one is the name of the operator and the date. A double click on any of them, brings up a more detailed form about each process, machine, (for security reasons I can not show it here)

There's also the name of who is in charge of this part's production. We can send a message to him through this form and ask him to stop/continue the production or ask for any kind of change.

Again to be able to have this data, even if the order is one order, for us it means manufacturing 312 components. And this is only one order. There are more orders. And if we don't manage it this way, who can take care of the mess?

If we don't have a reliable system to check these info, we have to go to shop and search for each one of those component and I don't need to explain how hard it would be.

You may not believe it. But this form feeds the production machines too. This database creates and sends all the NC data for CNC machines. The operator searches for the component he want to work on and click a button. All the necessary NC data is sent to his machine and he only presses the start button.

I hope I'm clear enough.

You have a better idea? I'm all ears.

Thank you for your interest and trying to help